Praveen Mishra, JMD, LSI Engineering & Consultants Ltd

The average cost of mining equipment downtime is a staggering $180,000 per incident. At this rate, the industry could incur $10 billion in costs per year. Mining companies assign 30-50% of their operating costs to equipment maintenance. It is a way to prevent downtime and loss of productivity. Thus, asset management plays a critical role in the mining industry. In this blog, we will discuss the importance, barriers, processes, strategies, and case studies of mining asset management.

Asset management is a coordinated approach for maintaining assets throughout their lifecycle. The life cycle includes steps from acquisition to decommissioning. Mining involves physical assets, including heavy equipment, machinery, processing plants, and site infrastructure. Managing assets well has advantages like -

The problem runs deeper than it seems. The mining equipment works under harsh conditions that makes maintenance a challenge. Let’s discuss why machinery maintenance is tough in mining:

Despite these challenges, a good asset management plan offers many benefits:

Managing the mining assets requires a structured plan of different components and practices. Practices ensure assets work at full capacity and efficiency to provide optimal operations. Here, we discuss components, strategies, metrics, and practices for an effective asset management.

Asset inventory forms the foundation for mining management strategies. Inventory is an up-to-date list of all the assets, their location, functioning status, age, maintenance history, and specifications. It is important considering the spread of machinery and equipment across mine site(s). Engineers can find underused assets and redeploy them using inventory.

Time-based maintenance techniques help monitor and improve asset performance.

Preventive maintenance entails periodic monitoring and servicing of equipment. Their regular upkeep prevents equipment failure, improves efficiency, and extends equipment’s life. Examples:

Another proactive approach to asset management is predictive maintenance. Data from IoT sensors fixed on the machinery can predict equipment failure. Thus, mining enterprises can service the assets before their breakdown. Softwares like APM Predict track predictive indicators and recognise early signs of breakdown.

Together, preventive and predictive maintenance can decrease unknown equipment downtime by 45%. Additionally, time-based maintenance helps identify under-performing assets and avoid over-maintenance that wastes resources.

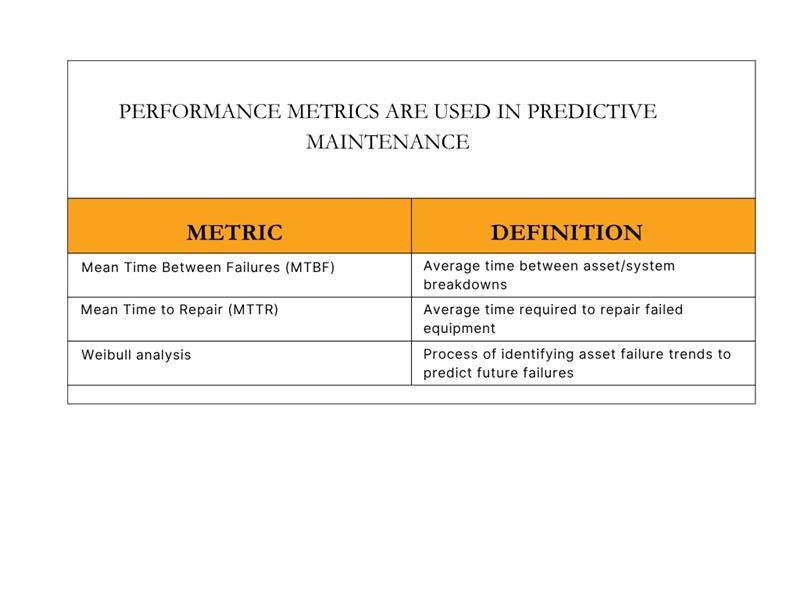

Predictive maintenance has following metrics:

Risk management is a well-defined plan to identify, assess, and remove risks associated with mining assets. It includes:

Health and safety risk assessment identifies hazards in asset's use, maintenance, and location. It protects workers, equipment, and the environment.

FMEA (Failure Mode and Effects Analysis) predicts potential failure points in assets and its impact on safety, performance, and operation. FMEA involves the following steps:

Condition-based asset management is useful in rugged environments where operational stress is high. For early detection of wear and tear, engineers use

After detecting a faulty signal, maintenance personnel can schedule service during planned breaks.

Asset lifecycle management oversees assets' lifespan from acquisition to disposal for optimal performance. Key aspects of this management are:

It determines equipment's use time, replacement, rebuilding, or upgrading time. The aim is to manage assets in a way that reduces total ownership expenses.

Management of mining assets transforming driven by innovation, environmental responsibility, and digitalization. Below are some of the most impactful developments:

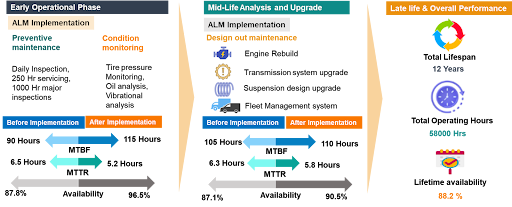

An open-cast Iron ore mine relies on dumpers for its operational procedures. These dumpers are critical assets that impact operational efficiency. The case study examines the ALM of new acquired dumpers based on reliability metrics and analysis.

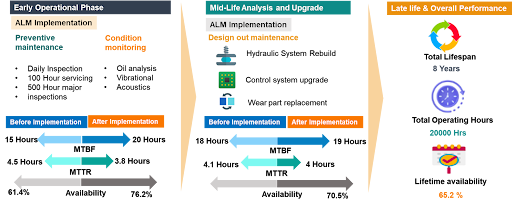

An underground zinc mine depends on jumbo drilling machines for blast holes and rock bolting. This case study explores the ALM of a new jumbo drill based on reliability metrics & analysis.

Effective asset management extracts most value of assets while reducing risks and costs. The management involves lifecycle planning, preventive maintenance, advanced analytics, ESG integration and more.

Despite harsh environments, limited spares, and workforce gaps, a strategic approach to managing assets reduces downtime, extends equipment lifespan, and enhances safety.

AI-driven insights, remote monitoring, sustainability-focused asset strategies, and ESG-aligned performance tracking are transforming mine asset management. As case studies, the implementation of structured ALM is already delivering measurable improvements.

In short, asset management is driving efficiency, safety, and innovation in mining. It is laying the foundation for a more productive and sustainable future.